博客

Accuracy over assumption: why the need for a single global carbon accounting model has never been greater

显著节省终端用户开支

The potential end-user savings using 艺术大师 Hydrate (ViHy) is greater than US$500M in CAPEX and US$50M per year in OPEX, 每发展.

特色的事实:

ViHy模型, 伍德的艺术大师软件的一个应用程序, is the world’s first industry-grade design and operational digital twin tool for hydrate risk quantification in gas dominant systems and consequent design and/or 生产 operations optimization.

在上游石油和天然气行业, hydrates have the potential to cause severe blockages in multiphase 生产 systems, 导致生产和收入的损失. 对必要的补救活动进行核算, 一次堵塞事件就可能造成数百万美元的损失.

面对这样的风险, operators have tended towards extremely conservative philosophies and procedures, such as overdosing and wholesale 生产 shutdown when MonoEthylene Glycol (MEG) supply is disrupted, even when there is little or no chance that a hydrate nucleation would occur. 这种策略是由于缺乏准确的判断而被迫采取的, 实时, operational knowledge of hydrate thermodynamics and mechanics in the pipeline.

实时的应用, multiphase simulation to 生产 operations is a particular area of expertise for Wood. 伍德 艺术大师 一套软件工具是健壮的吗, 实时管理石油和天然气, 二氧化碳和氢气管道和工艺系统. The highly flexible software provides many operational and commercial functionalities to help address the most complex gathering, 生产, 运输和加工问题, 根据客户安装的独特挑战进行定制.

Operators use 艺术大师 for both online and offline management of complex 生产 and sequestration systems as well as training, 假设分析, 可靠性和流动保证. 艺术大师提供重要的监控和咨询功能, 确保操作的完整性, 使生产操作管理和优化, 提供绩效评估和促进计划, 预测和数据分析.

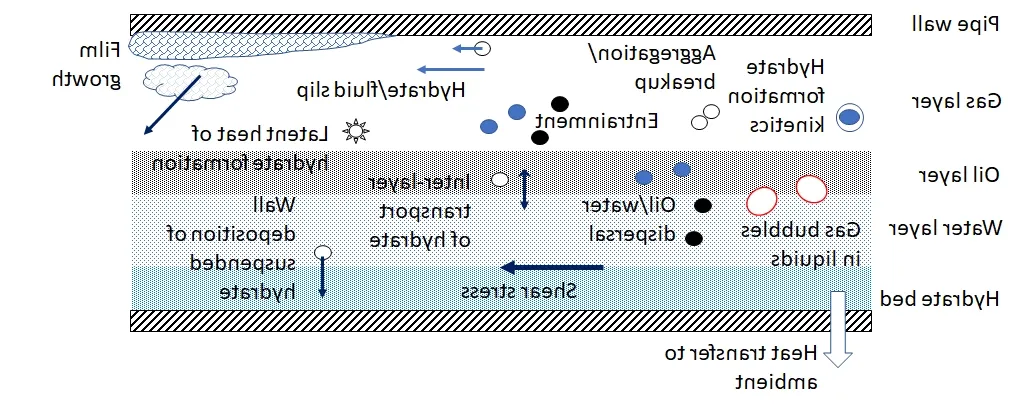

解决水合物的问题, 伍德与西澳大利亚大学(UWA)合作, to combine 艺术大师 with UWA’s hydrate kinetics model for gas-dominant systems. The resulting ViHy model is the world’s first industry-grade design and operational digital twin tool for 生产 operations that can quantitatively predict the hydrate formation and blockage risk.

Hundreds of millions of dollars are invested annually in facilities across the world to prevent hydrates from forming during 生产. Remediating hydrate blockages from upstream 生产 systems is normally an expensive and time-consuming exercise. 因此, normal hydrate management strategies revolve around completely avoiding hydrate formation, 基于极端保守的考虑.

在凝析气系统中, 这通常意味着昂贵的化学药品, 比如MEG, Low Dosage Hydrate Inhibitors (LDHI) or Methanol are dosed into 生产 fluids to prevent hydrates from forming, and the availability of these inhibitors is often considered 生产 critical.

目前, the risk factors of hydrate formation cannot be quantitatively analyzed by industry-grade software packages, 既不是在设计研究期间也不是在操作期间. 第一次, the ViHy model allows engineers to make decisions based on quantitative assessments of the true risk posed by hydrates. This represents an enormous opportunity for the gas condensate 生产 industry, with potential end-user savings greater than US$500M in CAPEX and US$50M per year in OPEX, 每发展.

另外, a hydrate risk assessment study was recently conducted using ViHy model for a large gas 生产 network in the Middle East, which helped the operator realize a potential savings of approximately US$125M over the life of field.

伍德 艺术大师 Hydrate Blockage Prediction Model was named a finalist in the 2023 Gulf 能源 Information Excellence Awards for Best Modeling Technology. This award recognizes the best use of modeling or simulation software to optimize plant design or engineering for increased safety, 效率和盈利能力. 海湾能源优秀奖项目联合了上游, 中下游行业领袖欢庆创新, forward thinkers bringing cutting-edge technological advancements to the energy sector.

横幅图片从左到右:阿扎德·赫萨莫迪尼, Executive President of Consulting at Wood; Eric May, CEO of the Future 能源 Exports Cooperative Re搜索 Centre and Professor at UWA; Miranda Taylor, CEO of the National 能源 资源 Australia (NERA); James Holbeach, Global Director of Production Optimization at Wood; Zachary Aman, Professor at UWA and Chair of the Board of Studies in Mathematical and Physical Sciences at the UWA School of Engineering